by Anaswara.J.S.(2016-2019)

anaswarajs@gmail.com

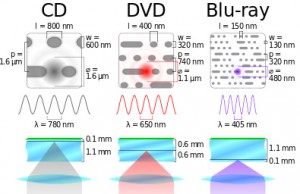

A compact disc or CD is a form of digital media. It is an optical device which can be encoded with digital data. When you examine a CD you can tell it is mainly plastic. In fact, a CD is almost pure polycarbonate plastic. There is a spiral track molded into the top of the plastic.

The surface of a CD is reflective because the disc is coated with a thin layer of aluminum or sometimes gold. The shiny metal layer reflects the laser that is used to read or write to the device. A layer of lacquer is spin-coated onto the CD to protect the metal. A label may be screen-printed or offset-printed onto the lacquer. Data is encoded by forming pits in the spiral track of the polycarbonate (though the pits appear as ridges from the perspective of the laser). A space between pits is called a

land . A change from a pit to a land or a land to a pit is a “1” in binary data, while no-change is a “0”.

Scratches Are Worse on One Side than the Other

Pits are closer to the label side of a CD, so a scratch or other damage on the label side is more likely to result in an error than one occurring on the clear side of the disc. A scratch on the clear side of the disc often can be repaired by polishing the disc or filling the scratch with a material with a similar refractive index.

Most of a CD is composed of a plastic called polycarbonate . The bottom layer is a polycarbonate layer where data is encoded by using tiny bumps on the surface. Above this layer is a reflective layer, which is typically made of aluminum (gold is also used, although quite rarely).

Above the reflective layer is a protective layer of lacquer and plastic, which shields the layers below it. The artwork or label is printed on the lacquer layer (i.e., on top of the CD) via offset printing or screen printing.

CDs store information digitally, i.e., with the help of millions of 1s and 0s. Data on a CD is encoded with the help of a laser beam that etches tiny indentations (or bumps, if you will) on its surface. A bump, in CD terminology, is known as a

pit, and represents the number 0. Similarly, the lack of a bump (known as a land ) represents the number 1. Hence, a laser beam can encode the required data into a compact disc by using pits and lands (0 and 1, respectively).

Now that you know how a CD is encoded with data, let’s take a look at how a CD player actually reads that stored data.

How does a CD player work?

There are two main components inside a CD player that help read a CD: a tiny laser beam (known as a semiconductor diode laser) and an electronic light detector (basically, a tiny photoelectric cell). When you switch on the CD player, an electric motor inside the player makes the CD rotate at a very high speed (the outer edge rotates at 200 RPM , while the inner edge spins at 500 RPM).